Welcome to HANSUN ELECTRIC TECHNOLOGY CO., LIMITED

Toggle Navigation

- Home

- About Us

- Products

- Crystal growth furnace

- Spray Pyrolysis system

- Plasma sputtering coater

- Magnetron Sputter coating

- Plasma cleaner

- Spin coater

- Thermal Evaporation Coate

- Battery R&D Equipment

- Atmosphere Furnace

- Muffle Furnaces

- Tube Furnaces

- Lab Hydraulic Press

- Grinding & Polishing Machine

- Dental Furnace

- Vacuum Oven

- Cutting Saw

- Laboratory Mill&Mixer

- Glove Box

- Accessories

- CVD Furnace System

- Powder Metallurgy Sintering Furnace

- Heat Treatment Furnace

- Vacuum Brazing Furnace

- Graphitization Furnace

- Purification Furnace Series

- Powder Metallurgy Equipment Series

- Dip Coater

- Doctor-Blade Film Coater

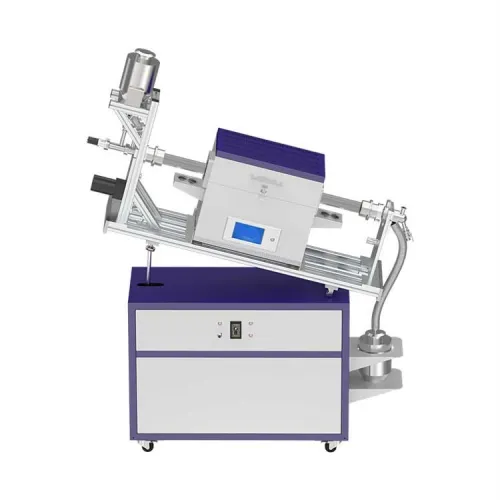

- Lab electrospinning

- Syringe pump

- Gas analyzer

- lab coating equipment

- Melting furnace

- Company News

- Request A Quote

- Feedback

- Contact Us